If you haven’t already heard of the notorious “death rays” created by solar reflections off the concave faces of the Vdara Hotel and 20 Fenchurch Street, I’d recommend reading the entertaining article, “A Brief History of Buildings that Melt Things”. Easy to laugh when it’s not your jag that’s melting.

Viñoly, the architect of both buildings was quoted by the Guardian as saying (with regard to 20 Fenchurch Street), “I knew this was going to happen, but there was a lack of tools or software that could be used to analyse the problem accurately”. Sigh.

It’s less obvious that regular windows can create hotspots. It turns out that “flat” windows aren’t very. They tend to be a bit concave. According to a LBNL white paper, factors that can lead to concavity include sealing the panels at altitude or with processes that heat the gas between the panes, argon depletion via diffusion through the seals, pressure differences between interior and exterior environments, and installation issues.

One might think, OK, so window glass may be slightly concave, but its reflectance is so low, how much damage could it do? Yes, clear glass reflects only 3-5% solar per surface at normal incidence, but low-E coatings, which are designed to reflect as much infrared radiation as possible, increase that by an order of magnitude. Combine high reflectance with concavity and you have a solar concentrator.

Vinyl siding is a common casualty of focused window reflections. According to the aforementioned LBNL paper, PVC heat distortion can start at temperatures as low as 142°F and melting can occur as low as 160°F.

An interesting case study, described in a technical service bulletin from Cardinal IG, involved grazing incidence reflections from a slightly concave clear glass window. These reflections illuminated siding oriented roughly perpendicular to the window with an irradiance of >1.8 kW/m2 (compared with 0.8 kW/m2 background irradiance). That was enough (with a minor contribution from roof shingle emission) to raise the siding temperature to 166°F and cause distortion.

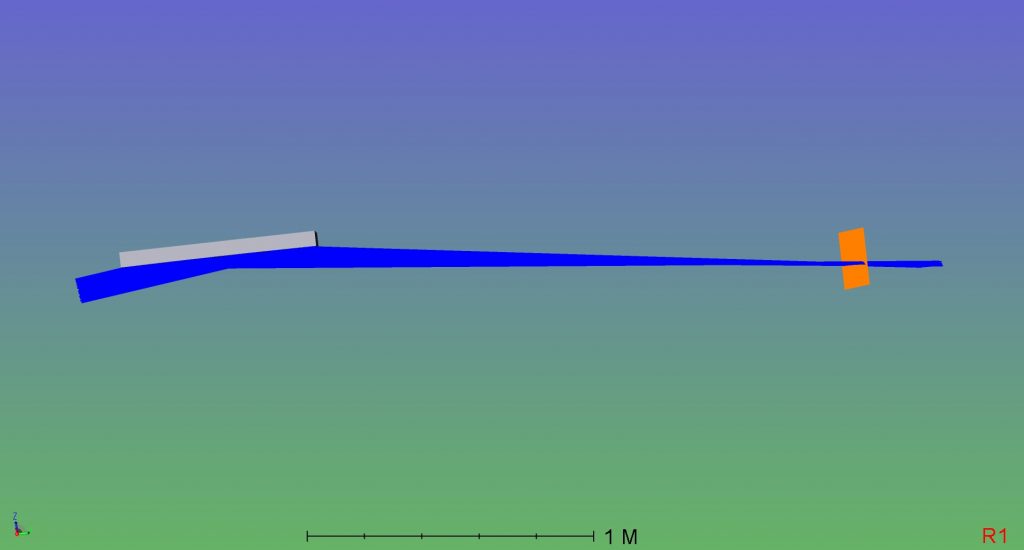

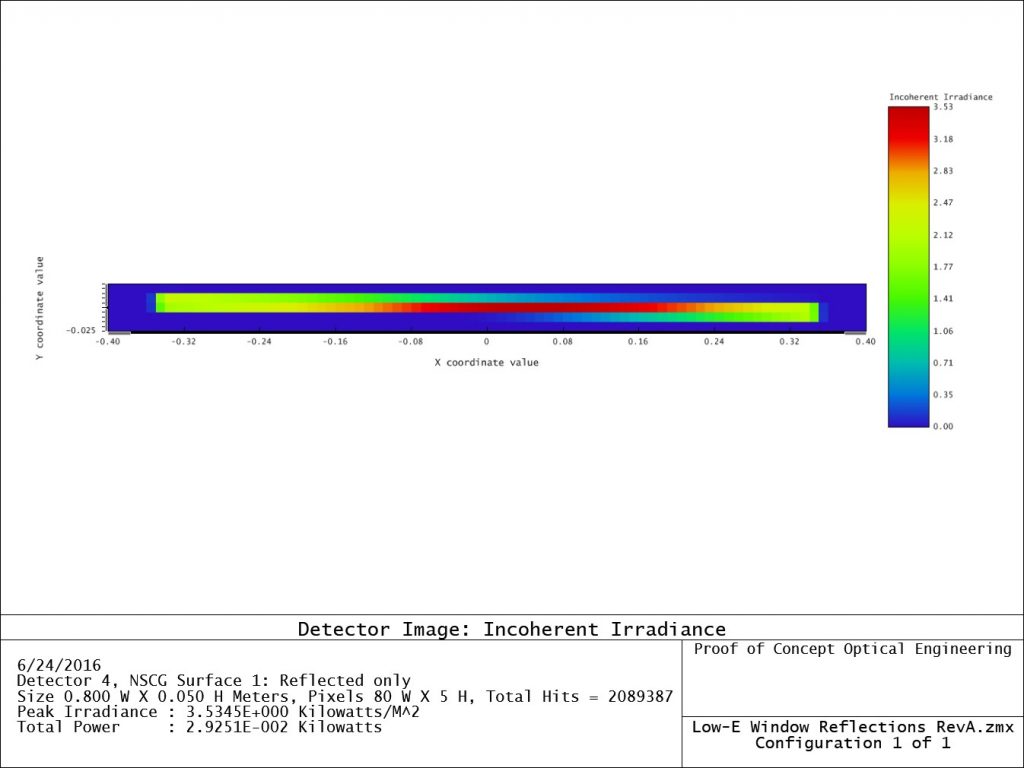

I quickly put together a model in Zemax to have a better look at what was going on and found that if the distance to the siding was approximately the focal distance of the window, the irradiance level could be much higher than what was measured in the case study. With a glass deflection of only 1/16″, a distance of 2.2 meters from the center of the window to the siding, a sun angle of 83 deg, and a solar reflectance of 50% at that angle, the reflected irradiance could be 3.5x the background irradiance level. All this intensity from a window curvature so subtle, you probably wouldn’t even notice it.

Much more realism can be added to a raytrace model like this. Solid models of the window frame and trim and the siding can be created in the software or imported as CAD objects and assigned material and coating properties. The efficacy of awnings or blinds can be evaluated. Reflections from glass with much more complex deformations can be modeled. Irradiance patterns on the siding can be predicted for the full solar trajectory at various times during the year.

Raytracing is a valuable tool for this type of analysis, as it provides quantitative results and can inform us as to how we can best maximize the energy efficiency of windows without posing significant risks to health or property.

Leave a Reply

You must be logged in to post a comment.